-

Fiber Optic Light-Honeycomb Star Ceiling Panel

Fiber Optic Light-Honeycomb Star Ceiling Panel -

Fiber Optic Starry Sky Light-Inkjet Panel

Fiber Optic Starry Sky Light-Inkjet Panel -

Hydra Starry Sky Ceiling Panel

Hydra Starry Sky Ceiling Panel -

Fiber Optic Star Light Traditional Installation

Fiber Optic Star Light Traditional Installation -

Fiber Optic Standard Starlight Ceiling Panel

Fiber Optic Standard Starlight Ceiling Panel -

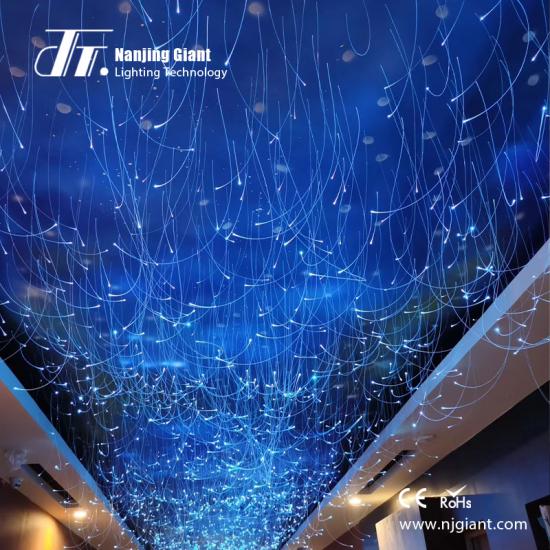

Fiber Optic Hanging Light Star Ceiling Panel

Fiber Optic Hanging Light Star Ceiling Panel -

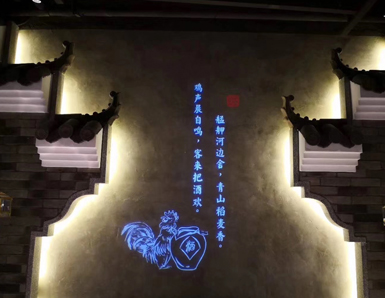

Fiber Optic Star Ceiling Custom Pattern

Fiber Optic Star Ceiling Custom Pattern -

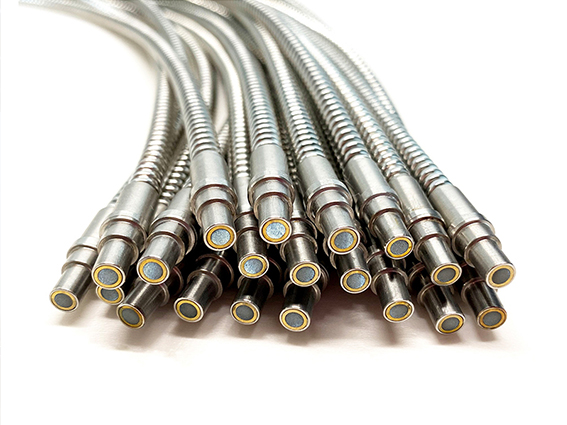

Optical Fiber Ring Light Guide

Optical Fiber Ring Light Guide

In the future, optical fiber is bound to play a greater role. The medical optical fiber market is growing at a significant rate owing to the increase in the application of glass optical fibers for minimally invasive surgery, the increasing demand for advanced diagnostic techniques, and the rapid development of medical optical fiber technology. The number of medical fiber optic bundle applications including X-ray imaging, ophthalmic lasers, phototherapy, laboratory and clinical diagnostics, dental head components, surgical and in vitro diagnostic instruments, surgical microscope illumination fibers and endoscopy fibers has increased significantly. In addition, the miniaturization of medical devices has also increased the demand for medical fiber optic technology.

Laser cosmetology is a new laser medical technology that has developed rapidly in recent years. The main principle of laser cosmetology is to use laser with high absorption rate of human tissue, and use its stimulating effect on biological tissue to hit the fractional laser on the skin to form many fractional micro-treatment holes. The micro-treatment holes are vaporized and thermally damaged. , to start the wound healing mechanism of the skin, let the skin re-grow the epidermis, and at the same time promote the production of collagen in the dermis through thermal stimulation. The stronger the laser energy, the stronger the irritation to the skin, the greater the damage, and the better the effect.

Our SMA905 fibers are made of high-quality polyimide-coated (PI) silica fiber. Polyimide has high modulus, high tensile strength and good chemical stability. It can withstand high temperature of 300°C for a long time, and high temperature of 490°C for a short time. In addition, it is very stable in terms of mechanical properties, fatigue resistance, flame retardancy, dimensional stability and electrical properties. Therefore, the optical fiber coated with this material has the characteristics of high temperature resistance and can be used for a long time in a temperature environment of 300°C.

IPv6 network supported

IPv6 network supported